Nearly 4500 machines are designed and manufactured each year in our 10 700 m2 factory in Alsace.

We are proud to be making high-quality machines in France so as to offer our users reliable, high-performance products. This is the process for making machines of this kind:

Imagine, develop, optimise and design our machines is the role of the Design Office. Our customers help us a lot for our inspiration.

Pieces up to 20mm thick are cut by this machine.

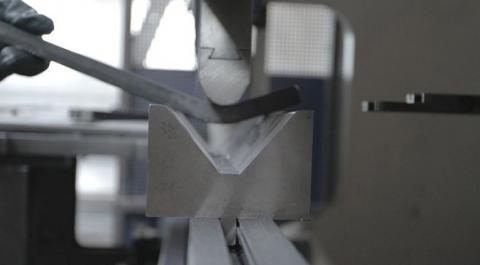

Parts up to 3000mm wide are folded by our CNC (Computer Numerical Control) machine.

Our bending machine is programmed according to the size of the tubes. Elasticity of the material allows very complex bending.

Depending on the part, the welding is manual or robotic.

Before assembly the parts are powder painted.

The final step is here, assembling and final control !